33

Company

Hanon Systems is a one of only two global

full-line automotive thermal solutions sup-

plier in the world. Headquartered in Korea

and with 39 manufacturing sites, four

global technical centers in 19 countries

across Asia, Europe, North America and

South Asia, the company employs more

than 15,500 people. In 2014, the company’s

global sales reached 5.4T KRW.

The European Technical Center (ETC) in

Germany is one in a network of global

development locations, each carrying a

unique set of capabilities. ETC’s on-site

development capabilities are multi-faceted,

from product development and R&D for

components and systems, to vehicle inte-

gration, prototyping and vehicle, compo-

nent and system testing. The R&D environ-

ment encourages out-of-the-box thinking

and unites the engineers in bringing

market relevant solutions to new chal-

lenges. Unique tools as well as a compre-

hensive and interconnected development

toolset support our R&D endeavors and

help see an idea through to a tangible

end product.

Technology

Hanon Systems provides innovative solu-

tions for eco-friendly and high-efficiency

thermal management to bring value to

customers and deliver occupant comfort.

Products that address regulatory require-

ments and meet the needs of consumers

in local markets include

•

Heating, Ventilation and Air Conditioning

•

Compressors

•

Powertrain Cooling

•

Fluid Transport

•

Electric, Hybrid and Fuel Cell Vehicle

Thermal Systems

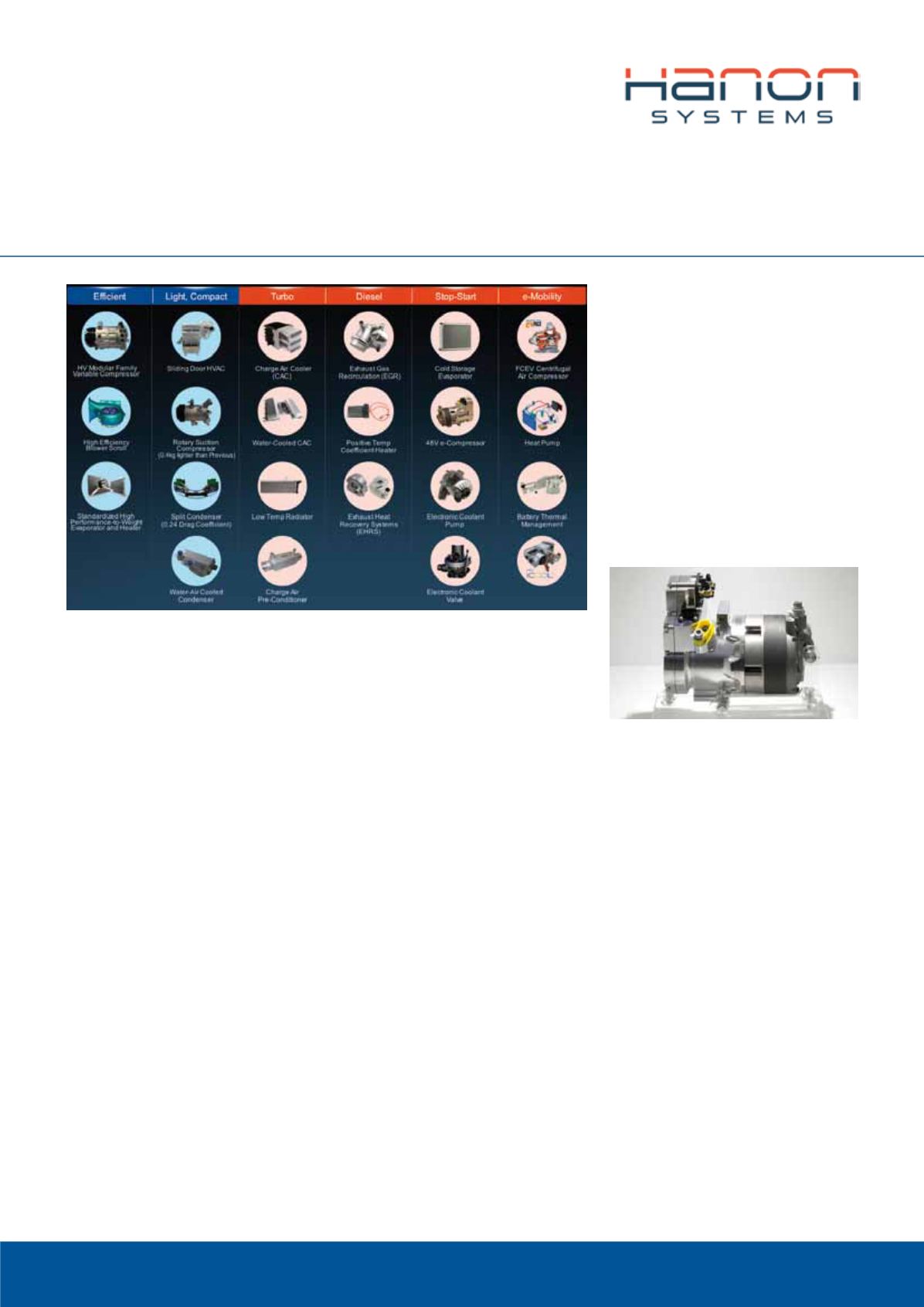

Electric Compressor

For traditional internal combustion vehi-

cles, the air conditioning compressor is

driven by a belt connected to the engine;

therefore, it can only operate when the

engine is running. Electric and hybrid

vehicles operate under different condi-

tions that preclude conventional com-

pressor designs. For both “green” vehicle

applications, Hanon Systems has devel-

oped an innovative solution – the electric

compressor.

Hanon Systems’ state-of-the-art design

includes an efficient scroll compressor

controlled by an on-board electric motor

and integrated power electronics. This

modular approach allows the same basic

packaging dimensions for the electric mo-

tor and power electronics to be designed

for different DC bus voltage levels, rang-

ing from 48V up to 500V applications.

The electric compressor operates indepen-

dently, enabling the cabin to be cooled

even when the engine is off. Its compact

design fits within the traditional belt-driven

compressor package space, minimizing

vehicle complexity in platforms that offer

hybrid-electric model variants.

Hanon Systems Deutschland GmbH