131

General Information

The University of Applied Sciences in Kiel

is the largest Applied Science Institution

in the State of Schleswig Holstein. In 2011

more than 6000 students were enrolled

with more than 1000 students in the Fac-

ulty of Computer Science and Electrical

Engineering. The Institute for Mechatron-

ics as a part of the faculty is offering ed-

ucation and research participation for

about 150 Bachelor and Master Students.

The Key Aspect is E-Mobility

The Institute for Mechatronics has a

strong focus on E-Mobility and its hard-

ware components which led to the es-

tablishment of the Schleswig Holstein

Competence Centre for E-Mobility

(

). In research pro-

jects e.g. the daily use of electric vehicles

(Peugeot Ion, EcoCarrier) is analyzed and

a new battery management system is de-

veloped. 5 Professors in the Institute are

offering specialized educational contents

like electrical traction and drives, electri-

cal circuit design, technical optics, me-

chanical design, system modeling and

control techniques.

The Bonding and Joining Lab

Professor Ronald Eisele is part of the E-

Mobility-Team and his courses and re-

search capabilities in the labs are consist-

ing of:

•

Thermal modeling, simulation and de-

sign of systems and components

•

Electrical and thermal design of power-

modules

•

Professional assembly processes for

bonding joining tasks

•

Testing and characterizing of power

electronic components

These capabilities are also offered for in-

dustrial development demands e.g. in

bilateral projects. By participating in re-

gional and nationwide research projects

these capabilities are constantly further

developed.

The scientific team includes experienced

engineers, Ph.D. Students (coopera-

tive graduations with other universities),

Bachelor and Master Students working

on their theses.

The team is designing and manufactur-

ing powermodule samples in industry-like

quality by applying:

•

Process-Development for Low-Temper-

ature Sintering of power semiconduc-

tors and passive components, termi-

nals, buffers and heatsinks

•

Multiple design approaches based on

different substrates (DBC, IMS, Lead-

frame)

•

Final encapsulation in frames or hard

epoxies

In the bonding and joining labs the team

is running a number of specially modified

equipment in order to support the indus-

trial partners in applying low temperature

sintering. A very promising new invest-

ment and research target is the combina-

tion of sintering and Cu-heavy wire bond-

ing (Orthodyne 3600+ new Cu-Version).

University of Applied Sciences Kiel

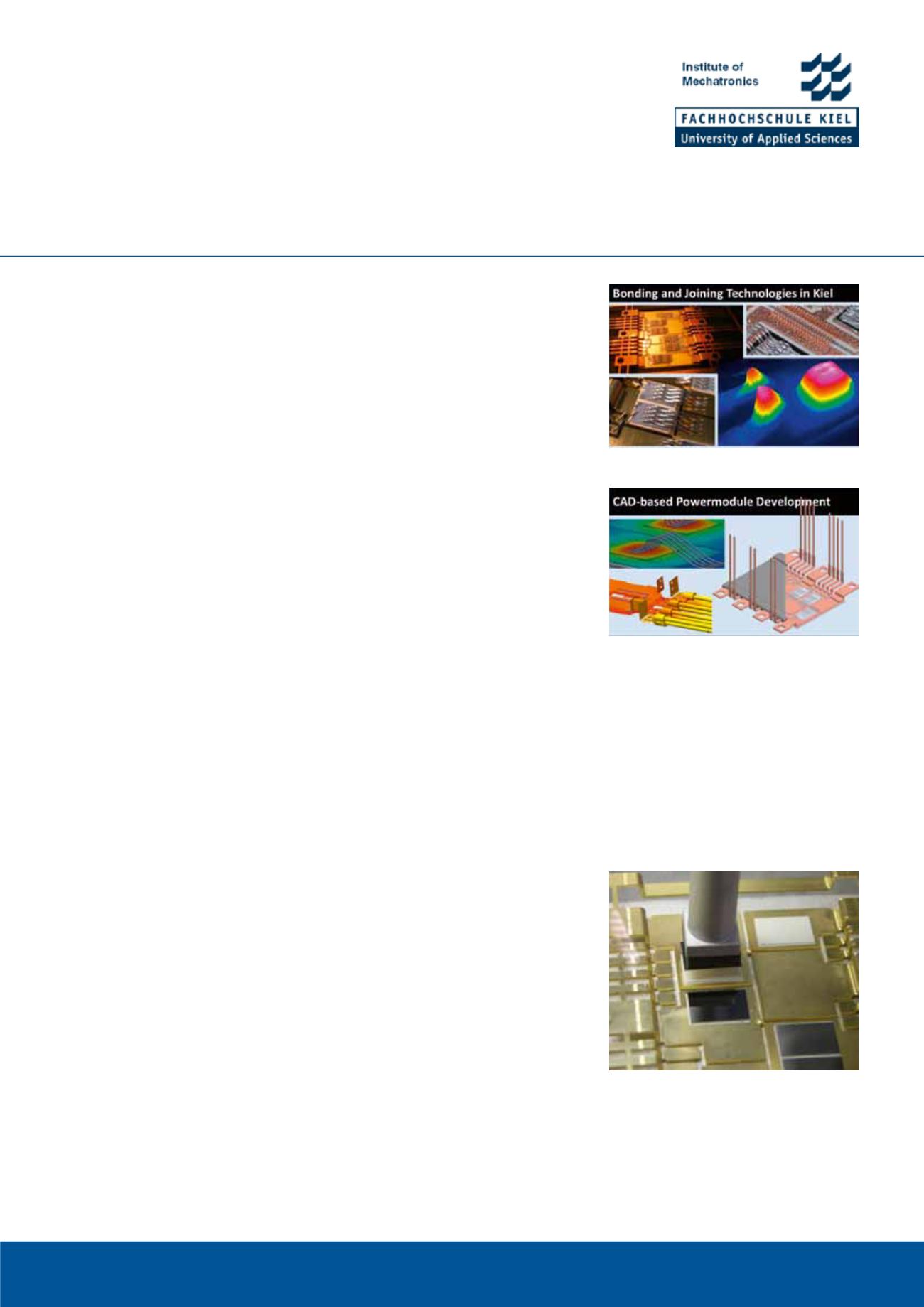

Sintered die attach on Leadframe

Bonding and Joining Technologies

CAD Power Module Development