56

Schweizer Electronic AG stands for state-

of-the-art technology and consultancy

competence. SCHWEIZER’s premium print-

ed circuit boards and innovative solutions

and services for automotive, solar, industry

and aviation electronics address key chal-

lenges in the areas of Power Electronics,

Embedding and System Cost Reduction.

Its products are distinguished for their su-

perior quality and their energy-saving and

environmentally-friendly features. Togeth-

er with its partners Elekonta Marek GmbH

& Co. KG, Meiko Electronics Co. Ltd. and

WUS Printed Circuit Co., Ltd., the com-

pany offers in its division electronics cost-

and production-optimised solutions for

small, medium and large series. In future,

SCHWEIZER plans to jointly tap the chip

embedding market together with its part-

ner Infineon Technologies AG.

With about 760 employees SCHWEIZER

achieved sales of 115.5 million Euro in

Fiscal Year 2015 (ending December).

The company was founded in 1849, is

managed by family members and listed

at the Stuttgart and Frankfurt Stock

Exchanges (ticker symbol „SCE“, „ISIN

DE 000515623“).

Excerpt of product portfolio

SCHWEIZER’s innovative solutions ad-

dress key challenges in the power elec-

tronics sector. Already today, the auto-

motive industry applies SCHWEIZER PCBs

which can operate up to 1,200 Ampere.

The

Heavy Copper Board

technology

e.g. is used today in high volume pro-

duction facilitating an ampacity of sev-

eral hundred Ampere. The

Inlay Board

Schweizer Electronic AG

applies copper inlays with a thickness of

up to 2 mm, creating areas on the PCB

which allow for current peaks of signifi-

cantly more than 1,000 Ampere.

Combining logic and power electron-

ics within one single PCB and ensuring

extremely good heat dissipation charac-

teristics the

Combi Board

is for appli-

cations such as high power 3 / 6-phase

drives, controlled power distributors and

all solutions requiring a combination of

logic and power.

Facilitating high thermal conductivity

and good electrical isolation at the same

time, the

IMS Board

can be applied in all

solutions, which require high power elec-

tronics such as DC/DC converter, motor

control units or as DCB/DBC substitute.

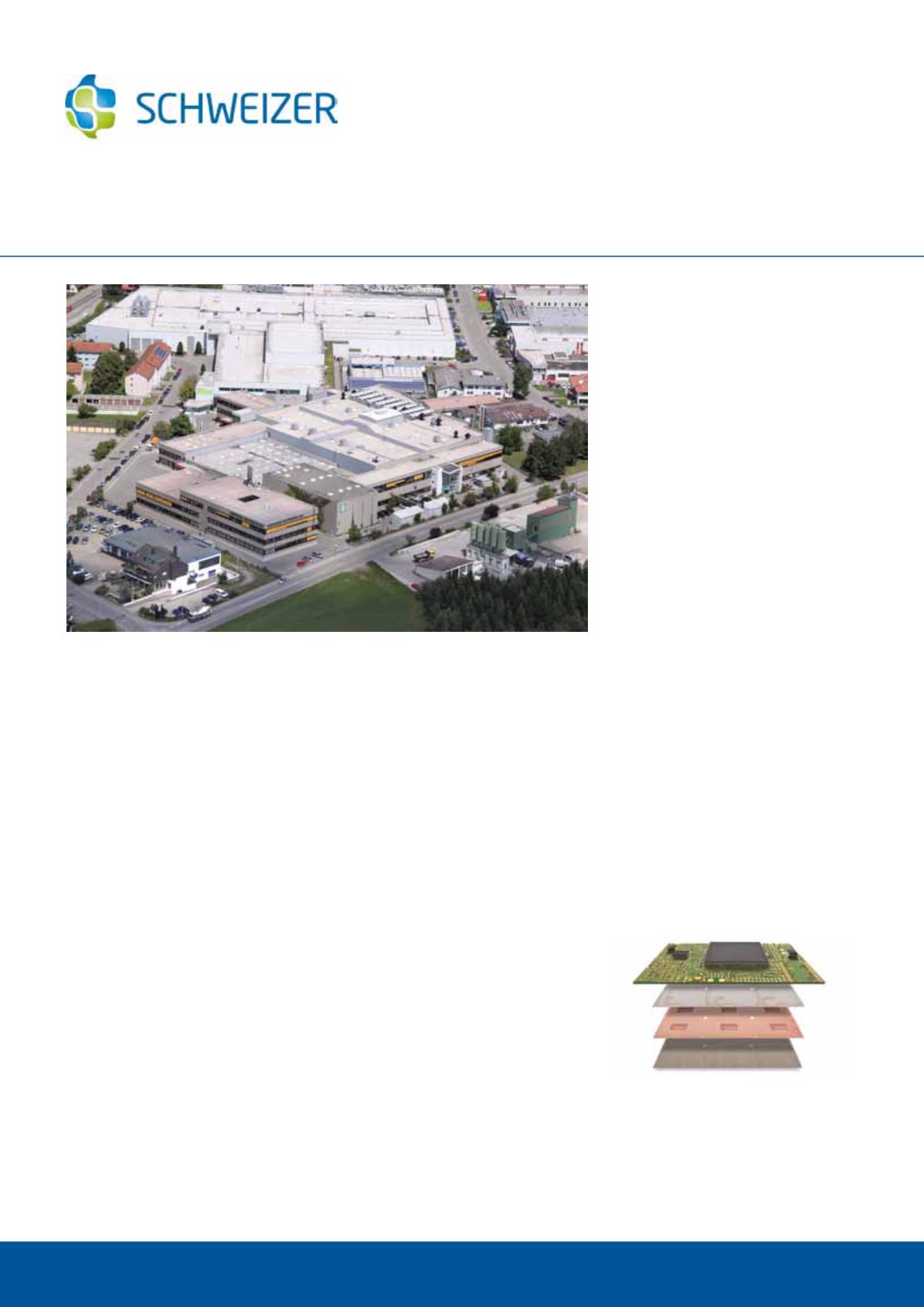

The

p² Pack technology

is based on

standard PCB processes, combined with

semiconductor solutions as MOSFETs,

IGBTs and SiC. It can be applied in power

electronic solutions with 3 or more phase

drives for e.g.: power steering, climate

compressors, high end fans as AC/DC

and DC/DC converters.

Smart p² Pack layup